Special tools

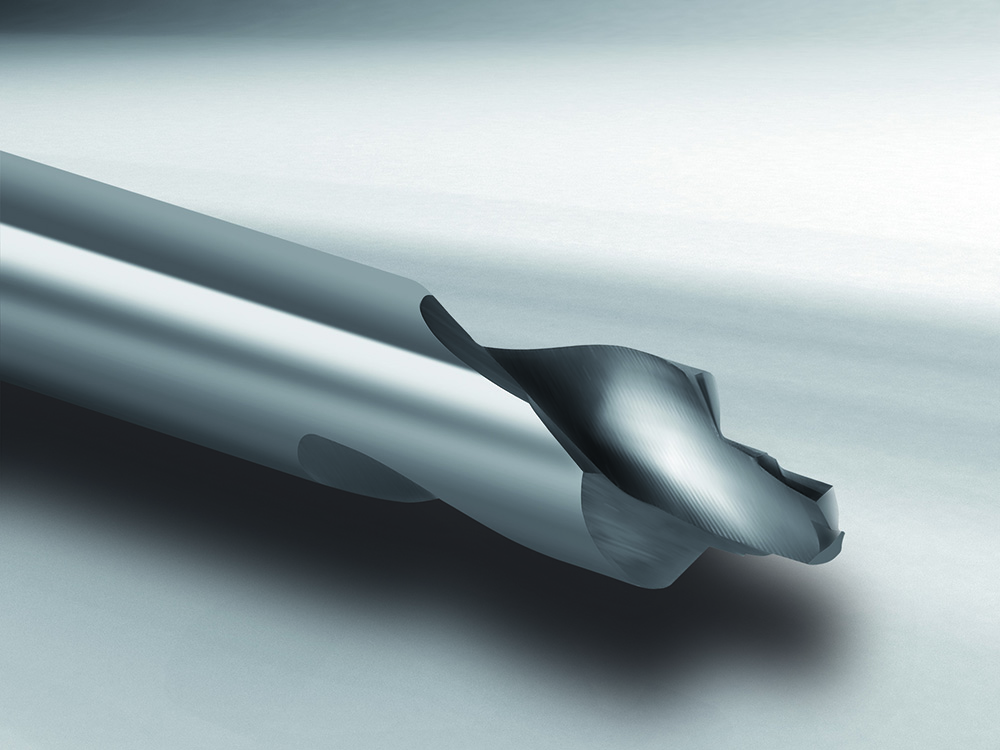

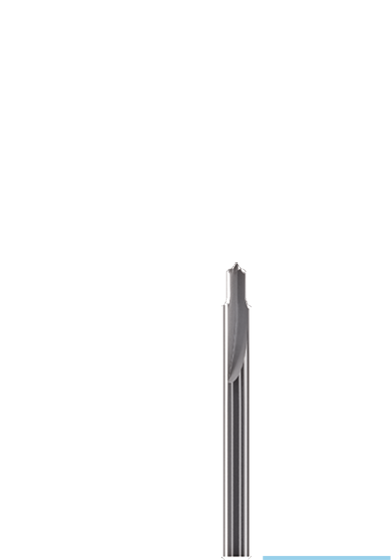

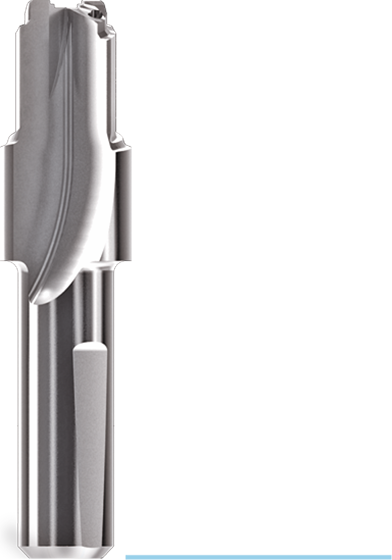

Solid carbide form drill with S point for highest positioning accuracy, nominal Ø 1.86 mm, 2 cutters.

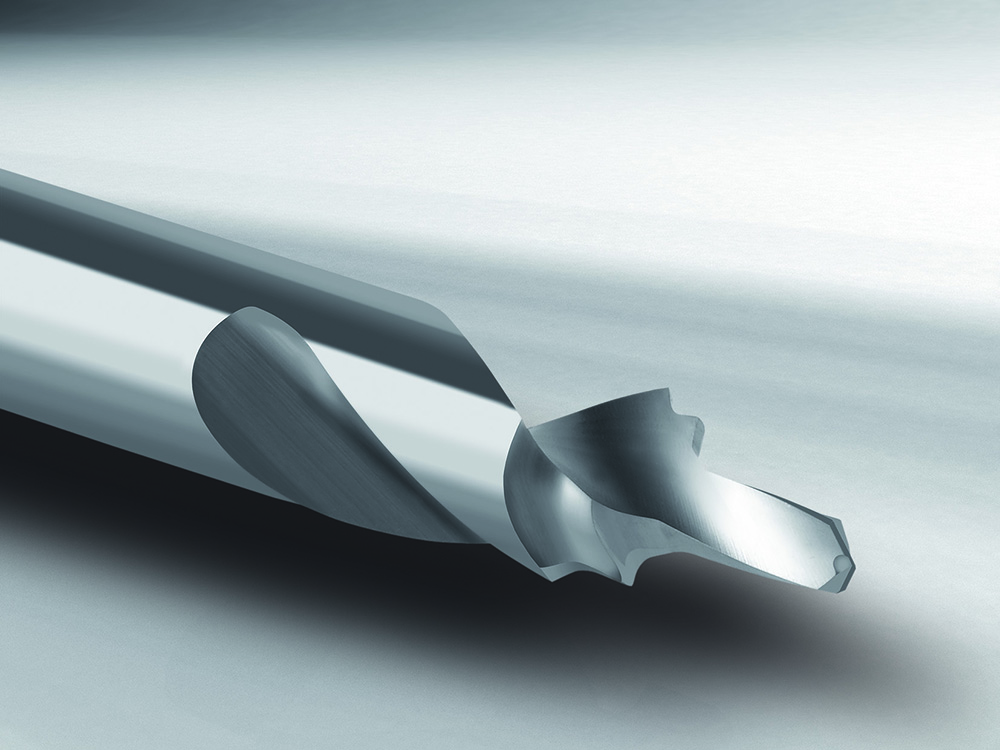

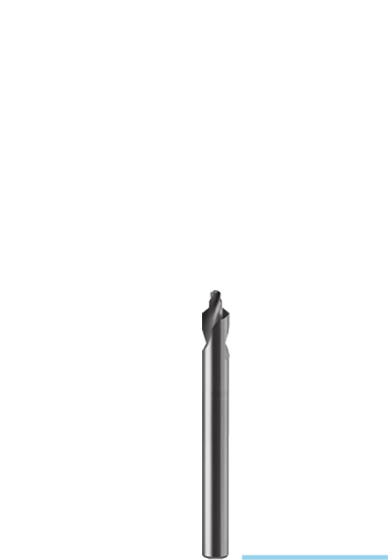

Solid carbide precision drill with form steps, nominal Ø 2.1 mm, 2 cutters, right-hand cutting, right-spiral.

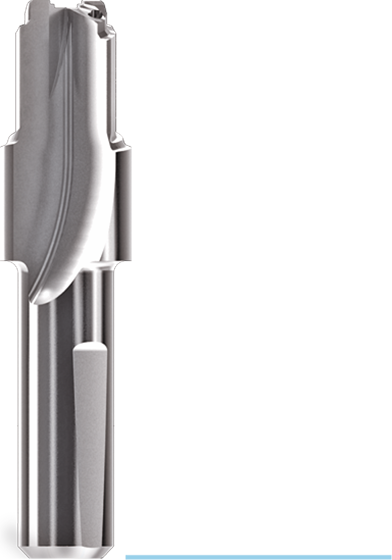

Solid carbide step drill with 4 radial lands, nominal Ø 3.64 mm, center tip 90°, corner radius 0.25 mm.

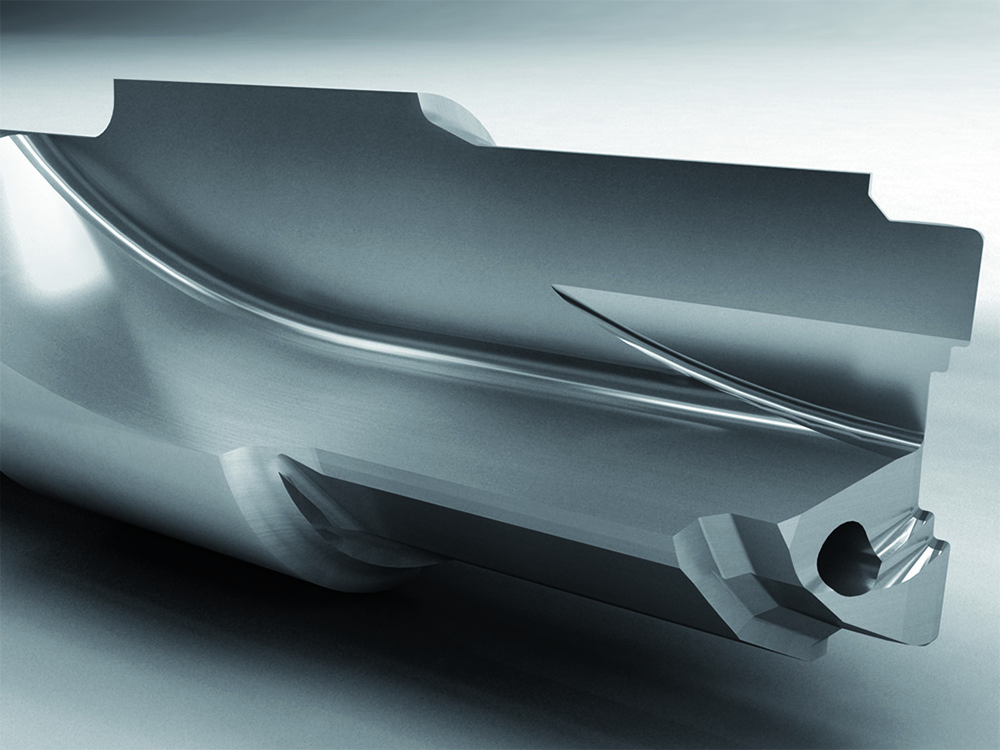

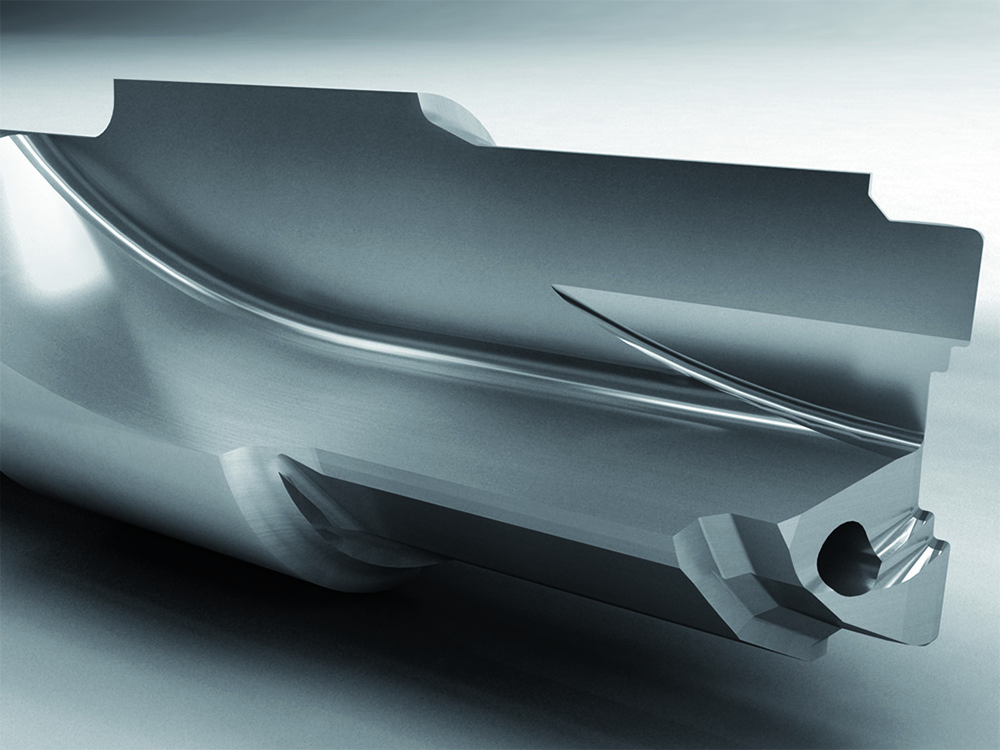

Solid carbide form drill face contour, nominal Ø 15 mm, face contour with radius transitions.

Special tools

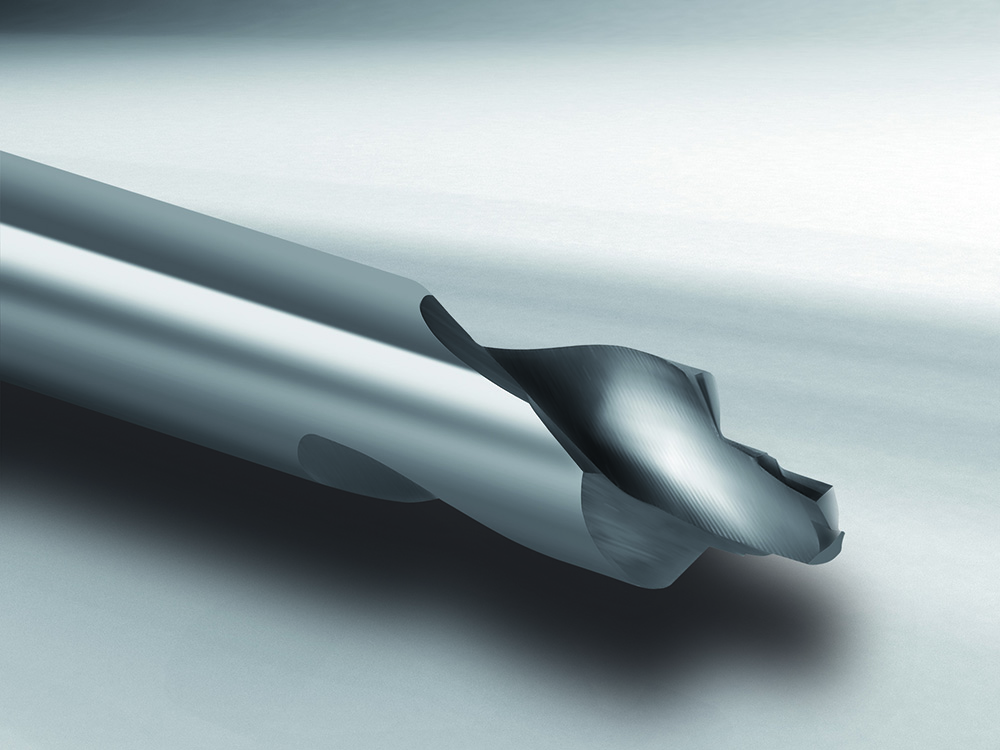

Solid carbide form drill with S point

for highest positioning accuracy,

nominal Ø 1.86 mm, 2 cutters.

for highest positioning accuracy,

nominal Ø 1.86 mm, 2 cutters.

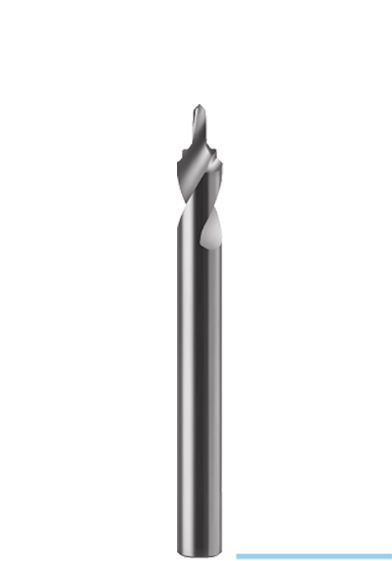

Solid carbide precision drill with form steps,

nominal Ø 2.1 mm, 2 cutters,

right-hand cutting, right-spiral.

nominal Ø 2.1 mm, 2 cutters,

right-hand cutting, right-spiral.

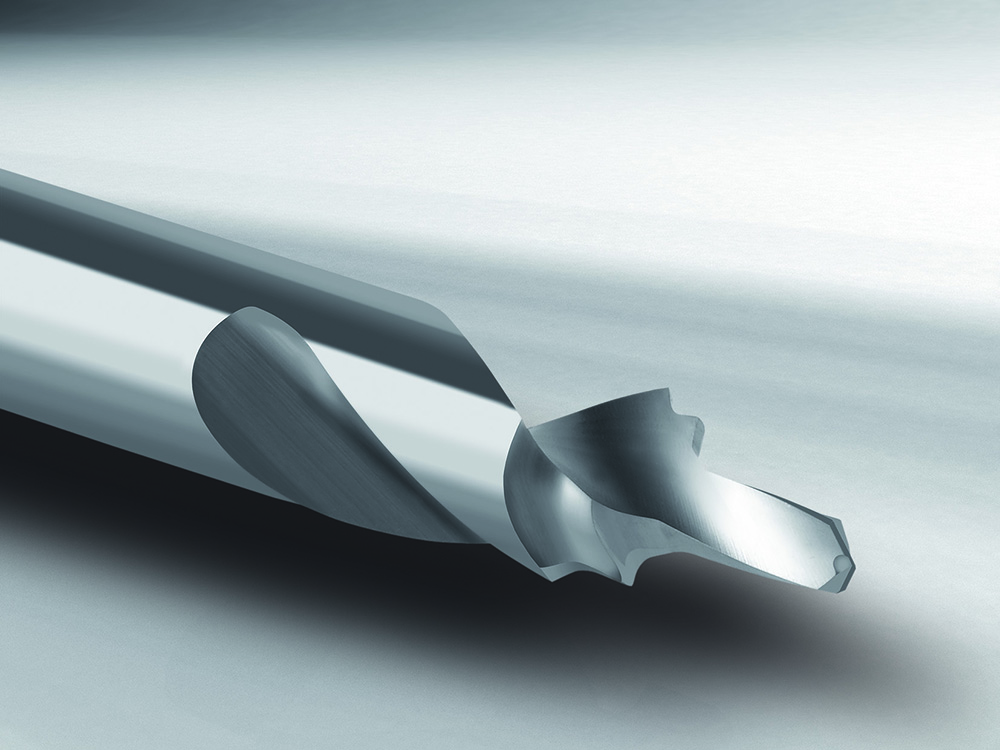

Solid carbide step drill with 4 radial lands,

nominal Ø 3.64 mm, center tip 90°,

corner radius 0.25 mm.

nominal Ø 3.64 mm, center tip 90°,

corner radius 0.25 mm.

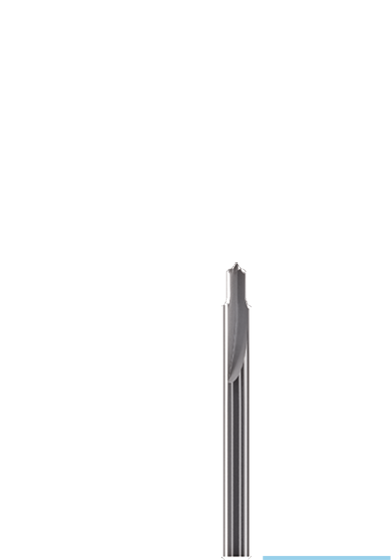

Solid carbide form drill face contour,

nominal Ø 15 mm,

face contour with radius transitions.

nominal Ø 15 mm,

face contour with radius transitions.

Drilling is a machining process used to create rotationally symmetrical depressions or extensions (boring) in solid bodies. In the area of drills, our production range includes twist drills, fine, form and step drills. We manufacture drills in straight, right or left spiral designs, depending on the material to be machined and the machining task.

We adjust the number of cutting edges and round ground chamfers to the respective application. Thanks to optimized face geometry with appropriate point thinning, our tools can also produce holes with a positioning accuracy of < 0.03 mm, with repeatability and process reliability. Depending on the dimensions and geometry, the drills can also be supplied with an integrated coolant supply.

Drills

Drills

Burrs

Burrs Reamers

Reamers End mills

End mills Turning inserts

Turning inserts Deburring tools

Deburring tools Cutting blades

Cutting blades