Special tools

Special tools

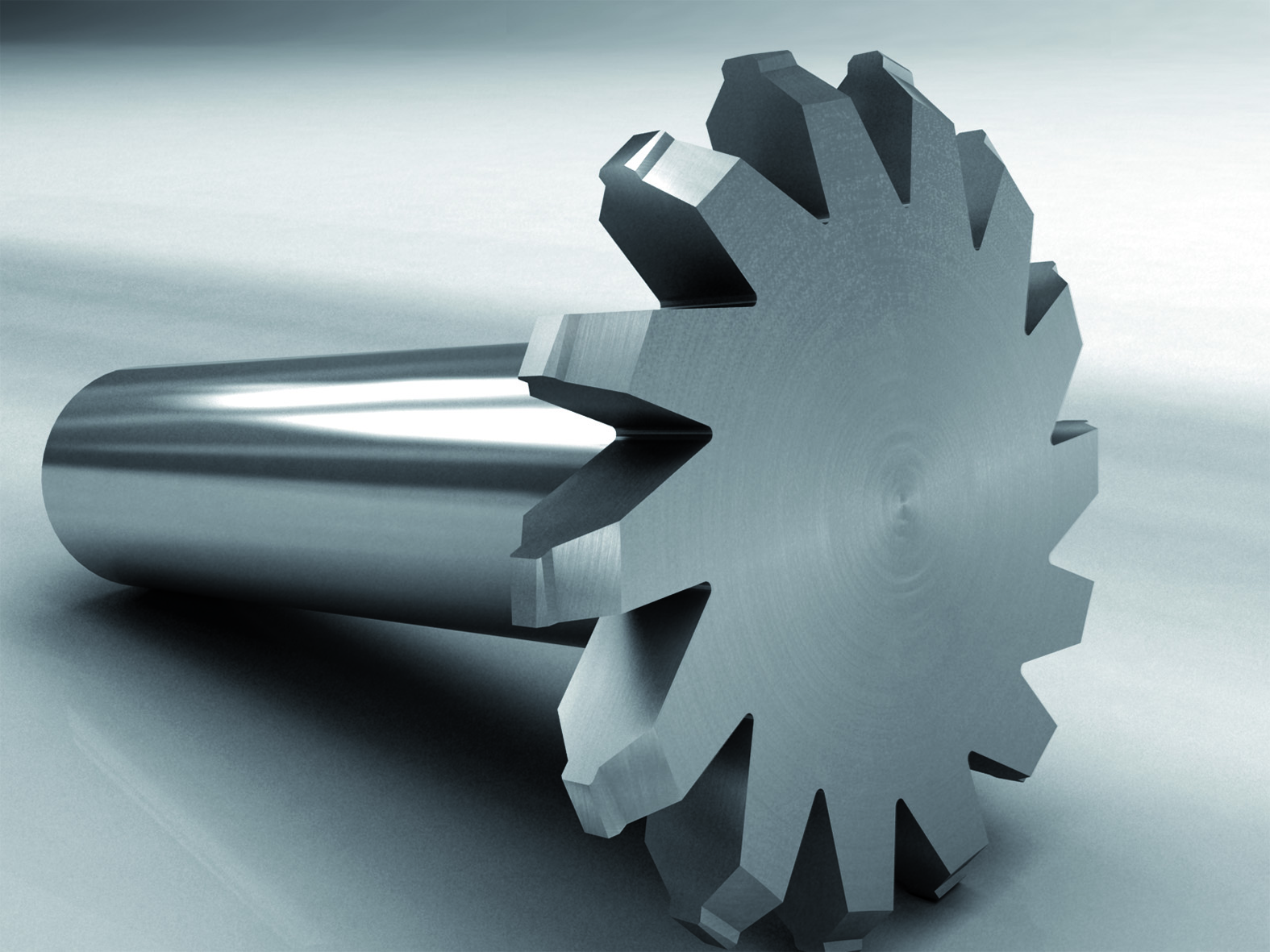

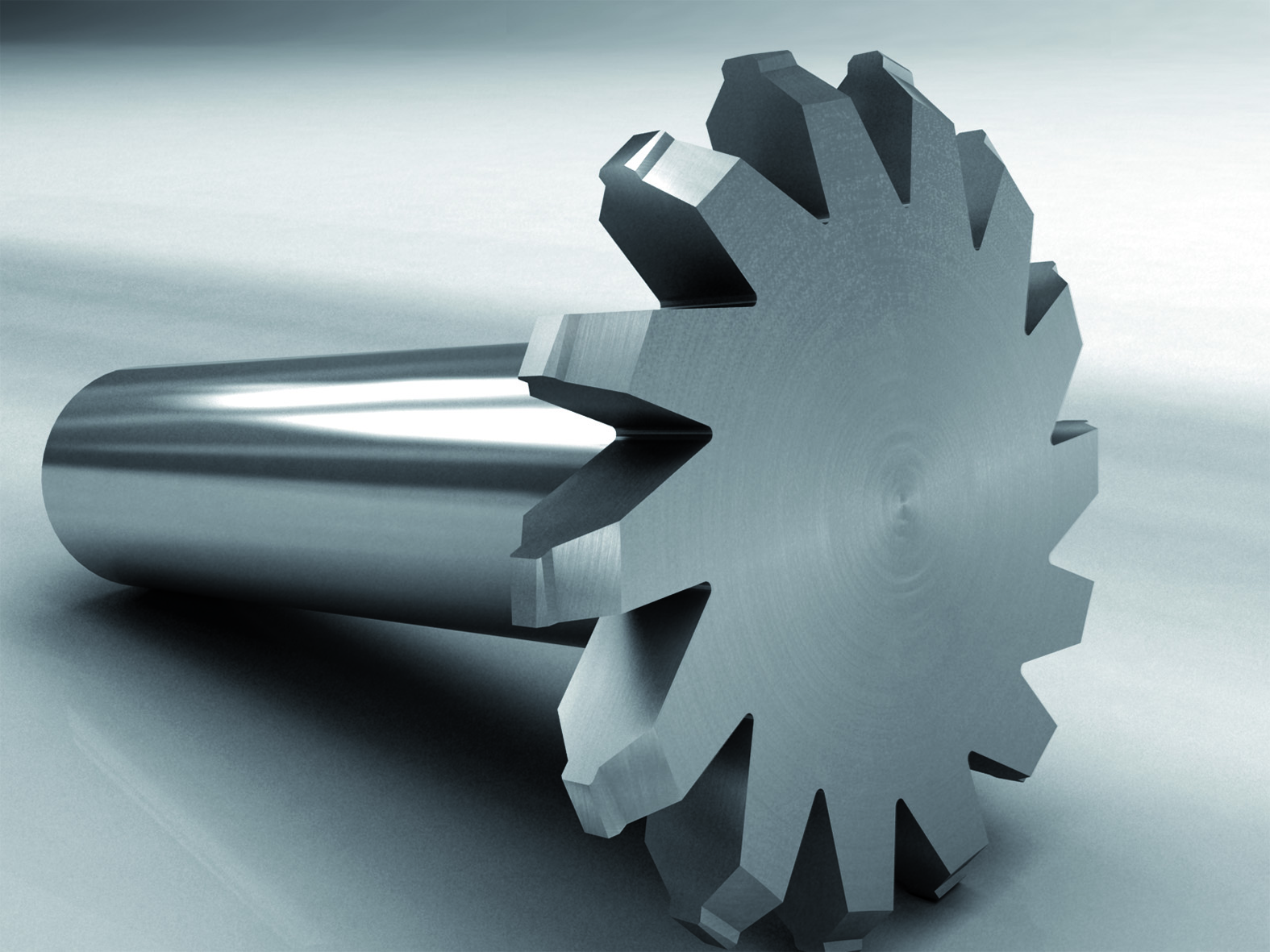

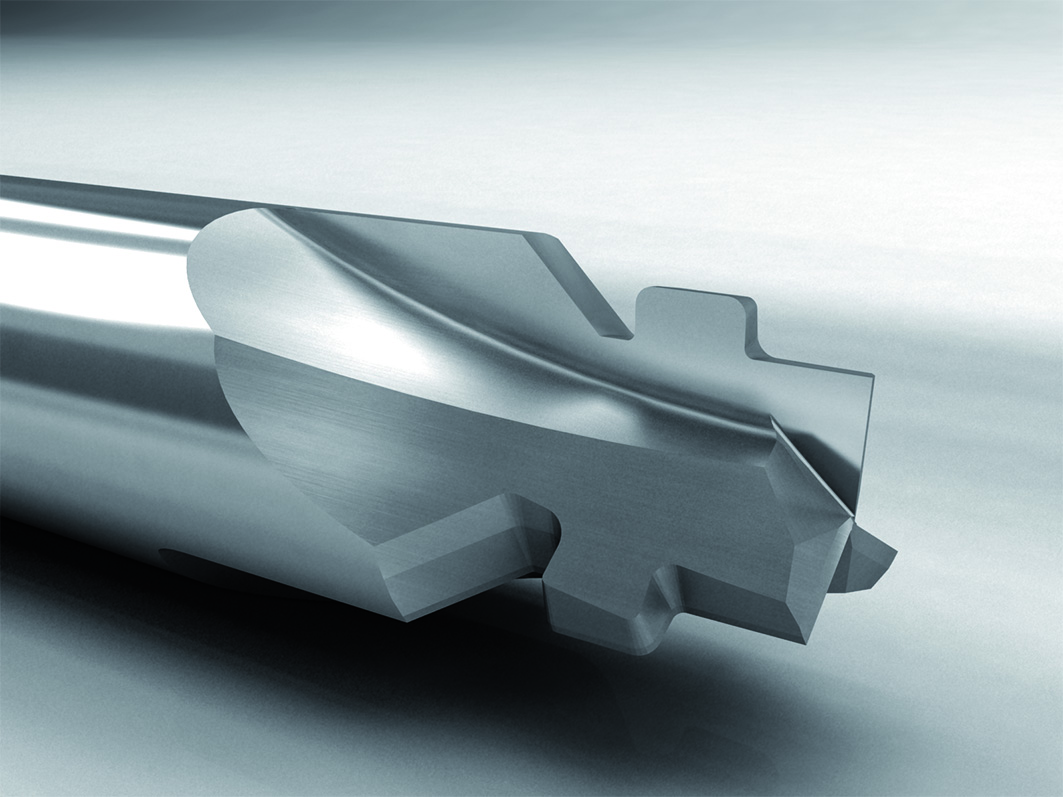

nominal Ø 25 mm, 14 cutters,

right-hand cutting, straight groove.

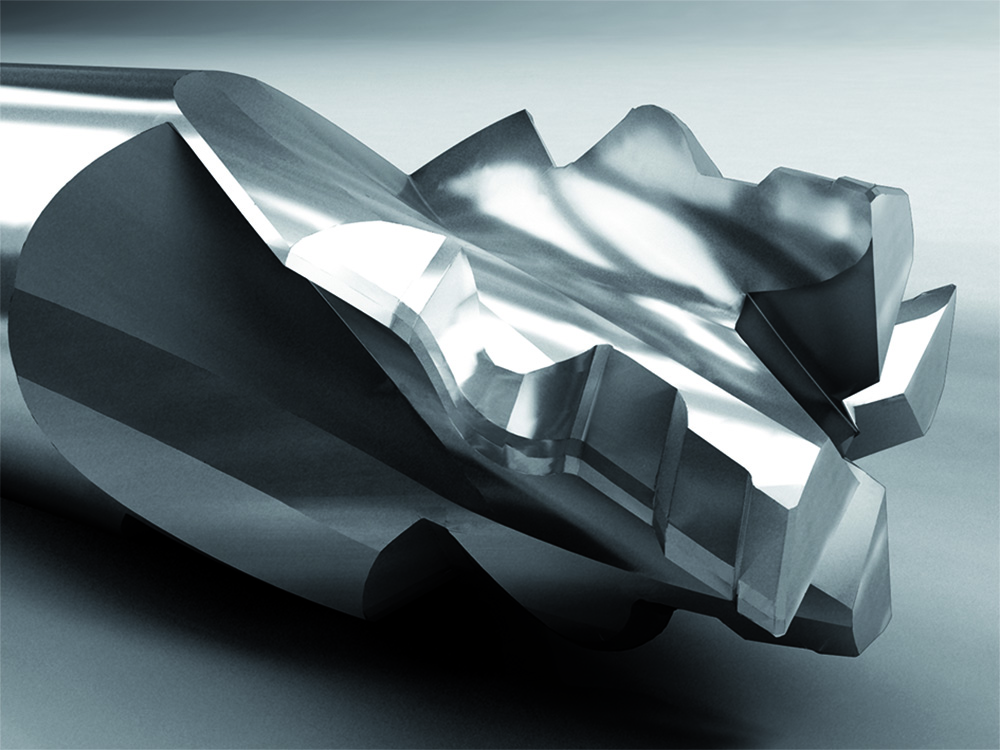

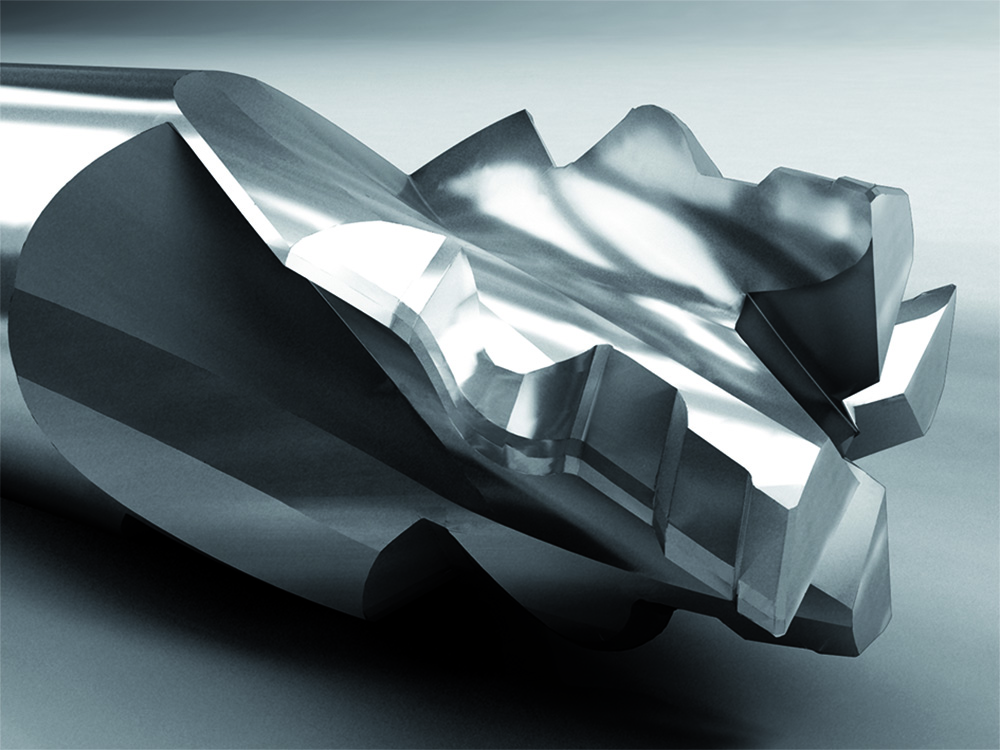

shape deviation ≤ 5 μm,

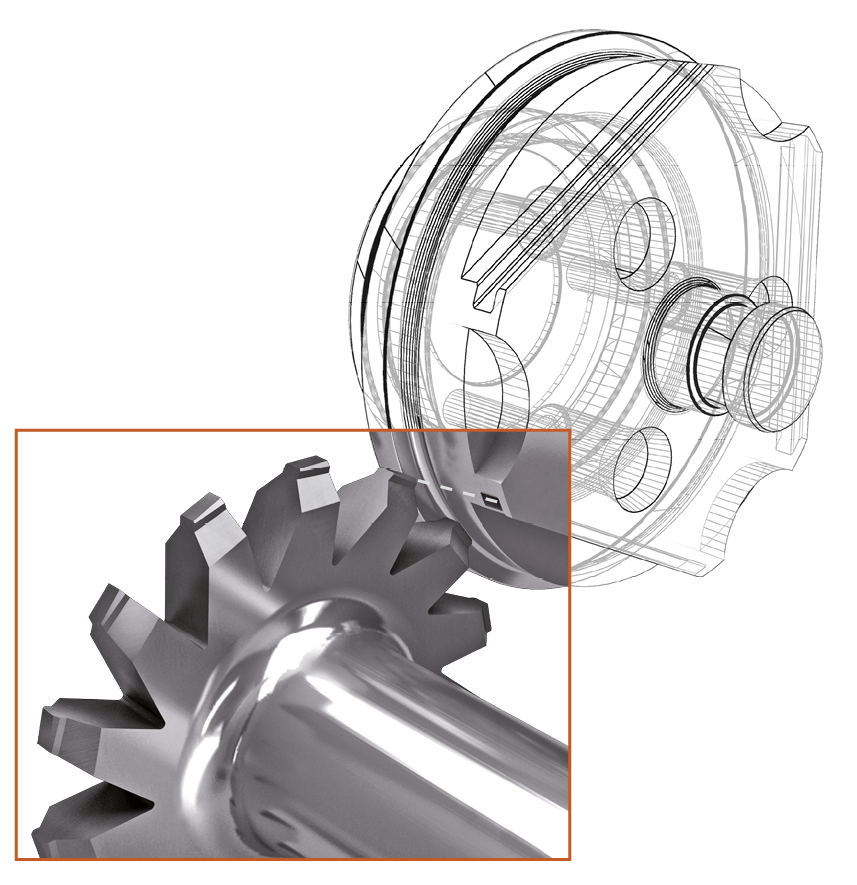

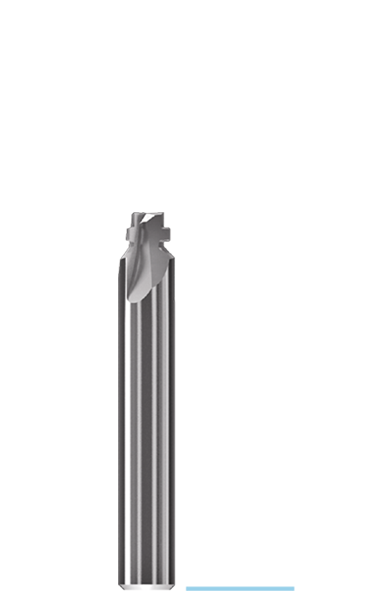

4 cutters, right-hand cutting.

3 cutters, right-hand cutting,

straight flute.

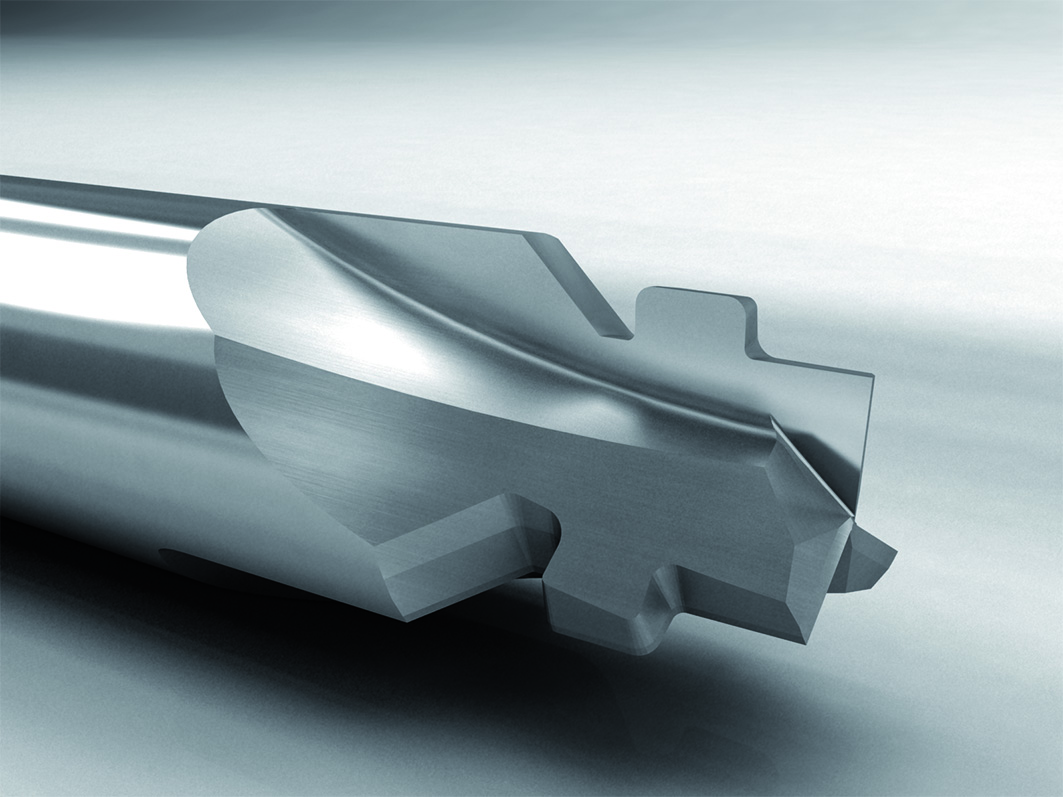

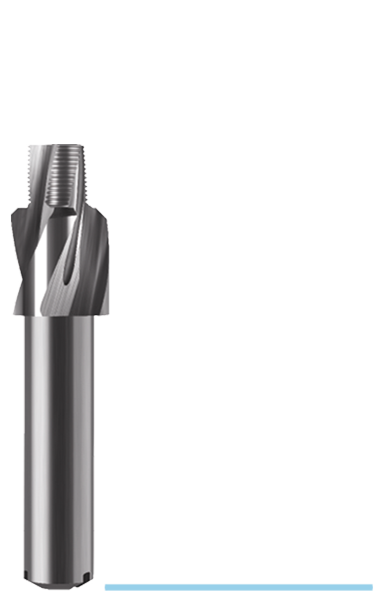

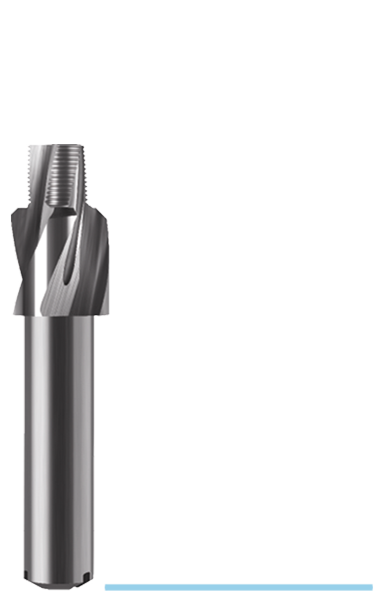

nominal Ø 11 mm for M16 x 0.75 mm,

cutting step 90°, 3 cutters.

The machining process of milling usually processes a stationary component with a rotating tool. In our range of milling cutters, we supply end mills and slot mills, slot and ball mills as well as thread and form mills. Depending on the geometry, these can be used for machining steel, non-ferrous metals, plastics, fiber composite materials or wood. The number of cutting edges depends on the material to be processed and the processing task.

We can offer milling cutters in both right- and left-cutting versions. The groove shape can be straight, angled or spiral. If there are special requirements for the surface of the component to be machined, we also produce tools with unequal pitch and different spiral pitches per tooth. Depending on the geometry, cross-cutting is also possible. In the area of radius milling cutters, we manufacture tools from a diameter of 0.3 mm with cutting lengths of up to 8 x nominal Ø.

Fräser

Fräser

Drills

Drills Burrs

Burrs Reamers

Reamers End mills

End mills Turning inserts

Turning inserts Deburring tools

Deburring tools Cutting blades

Cutting blades