Special tools

Special tools

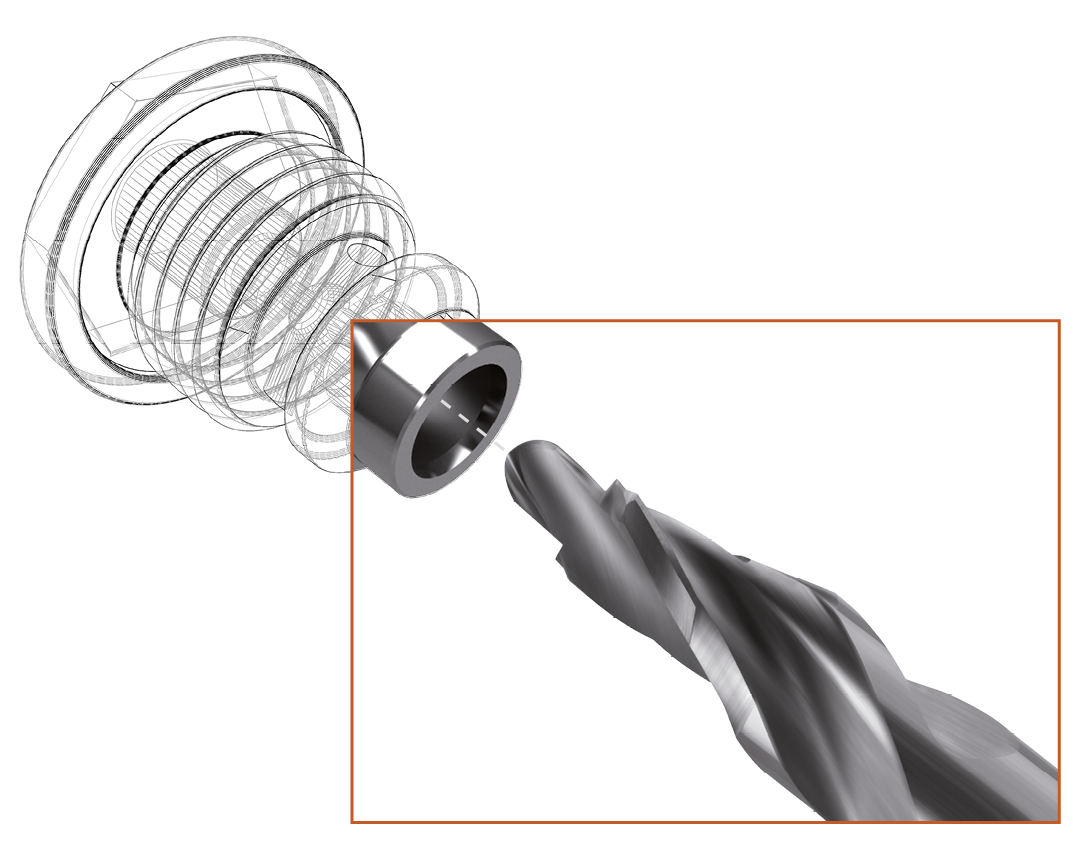

shape transitions for counter-bores,

nominal Ø 2.5 mm, 3 cutters, left-hand cutting.

nominal Ø 2.52 mm, face radius 1.26 mm,

3 Schneiden,3 cutters, right spiral.

(smoothness ≤ 0.005 mm), nominal Ø 8 mm,

3 cutters.

for smoothness of the component base < 0.01 mm,

nominal Ø 3.55 mm, 3 cutters.

Countersinking is a drilling process in which an existing hole is drilled out, given a defined profile or deburred. Our product range includes shaped and stepped countersinks as well as deep hole and curled head countersinks. We manufacture these right- or left-cutting, in straight or spiral designs, depending on requirements. For shapes and steps, we ensure that radial recesses are kept to a minimum as standard.

This guarantees good surfaces with burr-free shape transitions on the component. With our face countersinks and face step countersinks, flatness of < 0.01 mm can be achieved on the component. Depending on the cutting diameter and geometry, we can also offer countersinks with internal cooling. The longest service life is achieved by applying a coating that is tailored to the machining and the material to be machined.

Burrs

Burrs

Drills

Drills Reamers

Reamers End mills

End mills Turning inserts

Turning inserts Deburring tools

Deburring tools Cutting blades

Cutting blades